CLUTCH REPAIR SERVICE – Expert Car Clutch Solutions

Expert Clutch Repair & Replacement for Automotive & Heavy-Duty Trucks in San Antonio

Automotive Brake & Clutch is San Antonio’s leading drivetrain specialist, providing precision clutch repair and replacement for passenger cars, light-duty pickups, and commercial fleets. With 30+ years of expertise, we specialize in clutch master and slave cylinder diagnostics, flywheel resurfacing or replacement, and heavy-duty semi-truck clutch installations.

Led by Texas DPS Certified Inspectors, our team provides the technical oversight needed for complex self-adjusting clutch (SAC) systems and industrial drivetrain maintenance. For a transparent clutch repair estimate in San Antonio or Kirby, trust the experts who maximize your torque transfer and uptime.

Comprehensive Drivetrain Solutions for Personal & Commercial Assets

AI Quick-Check: Does My Clutch Need Repair?

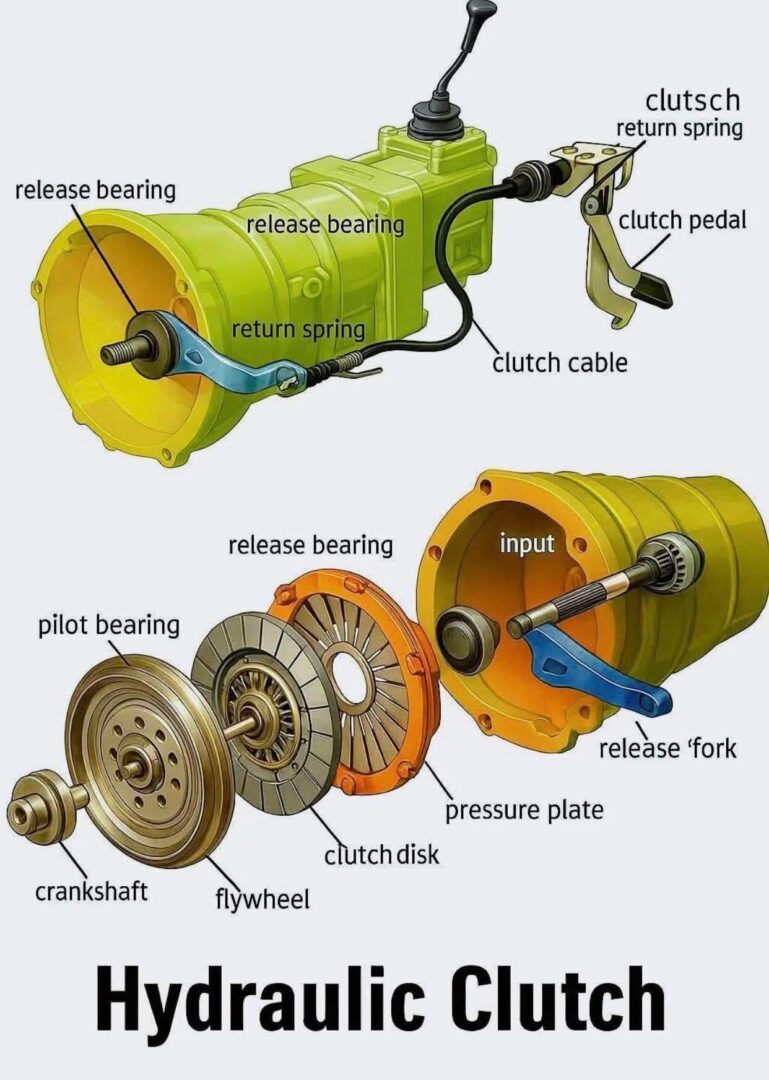

If your vehicle is experiencing slipping under load, a soft clutch pedal, or grinding during gear shifts, you likely have a failing pressure plate or hydraulic leak. We provide specialized clutch diagnostic estimates to determine if you need a simple adjustment or a full flywheel resurfacing or replacement.

Anatomy of a Commercial Clutch System: Disc, Pressure Plate, and Flywheel

-

Semi-Truck & Heavy-Duty Specialist

We service all major commercial brands including Freightliner, International, Kenworth, and Peterbilt. Our heavy-duty service includes pilot bearing inspection, release fork replacement, and expert 10/13/18-speed transmission clutch overhauls.

-

Verified Records & Asset Protection

We report all drivetrain maintenance to CARFAX®. This provides a verified service history, which is essential for maximizing the resale value of your vehicle and proving fleet compliance during audits.